In the ever-evolving world of automobile manufacturing, Toyota has established itself as a pioneer in quality management and problem-solving methodologies.

Toyota’s commitment to continuous improvement has resulted in the development of several problem-solving techniques that have revolutionized the industry.

In this article, we will delve into the various problem-solving methods employed by Toyota and explore how they have contributed to the company’s success.

Toyota Problem Solving Methods

Toyota’s problem-solving methods are deeply rooted in its renowned manufacturing philosophy, the Toyota Production System (TPS). The TPS aims to eliminate waste, improve efficiency, and ensure quality throughout the production process.

By implementing various problem-solving techniques, Toyota has been able to identify issues, find root causes, and implement effective solutions. Here are 13 major Toyota problem solving methods:

1. The Toyota Production System (TPS)

The Toyota Production System (TPS) serves as the foundation for Toyota’s problem-solving methods. It is a comprehensive approach that encompasses various principles and techniques, including just-in-time production, continuous improvement, and respect for people. The TPS emphasizes the elimination of waste and the pursuit of perfection in all aspects of manufacturing.

2. 5 Whys

The 5 Whys technique is a simple yet powerful problem-solving tool used by Toyota. It involves asking “why” multiple times to get to the root cause of a problem.

By repeatedly asking “why,” Toyota aims to uncover the underlying issues rather than just addressing the symptoms. This method helps identify the true cause of a problem and enables the implementation of effective countermeasures.

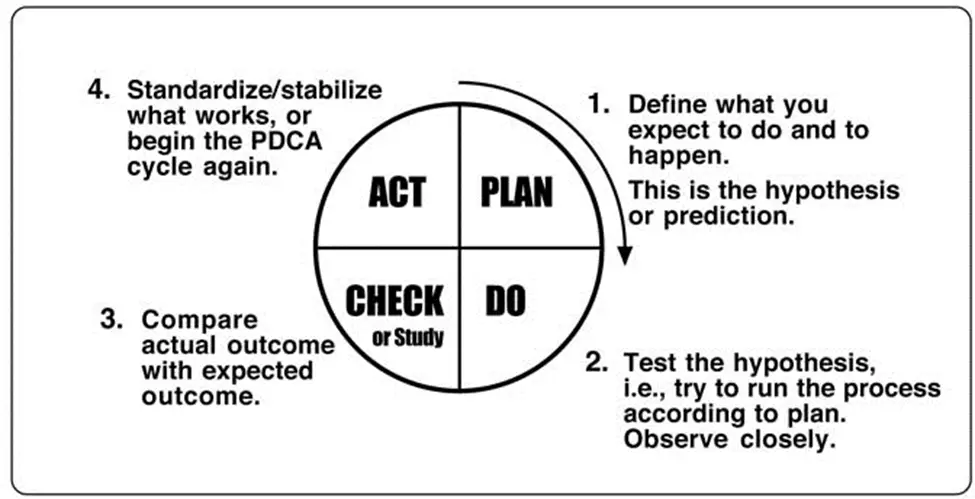

3. PDCA (Plan-Do-Check-Act)

PDCA, also known as the Deming Cycle, is a problem-solving approach that emphasizes continuous improvement. It involves four steps: Plan, Do, Check, and Act. In the Plan phase, Toyota defines the problem and develops a solution.

In the Do phase, the solution is implemented on a small scale. The Check phase involves evaluating the results, and in the Act phase, Toyota standardizes the successful solution and implements it on a larger scale. See more!

4. A3 Problem-Solving

A3 problem-solving is a structured approach used by Toyota to tackle complex problems. It gets its name from the A3-sized paper used to document the problem, analysis, and proposed countermeasures.

The A3 problem-solving process involves clear problem definition, root cause analysis, countermeasure identification, implementation planning, and follow-up to ensure sustained improvement.

5. Kaizen

Kaizen, meaning “change for the better” in Japanese, is a continuous improvement philosophy embraced by Toyota. It encourages all employees, from the assembly line to the management level, to seek small, incremental improvements in their work processes.

Kaizen fosters a culture of continuous learning, collaboration, and problem-solving, resulting in enhanced productivity and quality.

6. Poka-Yoke

Poka-Yoke is a method employed by Toyota to prevent errors and defects at the source. It involves implementing foolproof mechanisms and devices that make it nearly impossible to make mistakes or produce faulty products.

By incorporating Poka-Yoke techniques, Toyota minimizes the occurrence of defects and ensures higher levels of quality and customer satisfaction.

7. Jidoka

Jidoka, also known as autonomation, is a key principle of the Toyota Production System. It empowers machines and operators to detect abnormalities and stop the production process when issues arise.

Jidoka aims to build quality into the manufacturing process by preventing defects from being passed downstream, thus ensuring higher quality standards and reducing waste.

8. Six Sigma

Toyota utilizes the Six Sigma methodology to improve process performance and minimize defects. Six Sigma emphasizes the use of statistical analysis and data-driven decision-making to identify and eliminate variations in processes. By implementing Six Sigma, Toyota strives for perfection by targeting a defect rate of fewer than 3.4 defects per million opportunities.

9. Lean Manufacturing

Lean Manufacturing is a systematic approach that aims to eliminate waste and streamline production processes. It focuses on maximizing value while minimizing resources, time, and effort. Toyota has been a proponent of lean manufacturing principles, implementing techniques such as value stream mapping, just-in-time production, and continuous flow to optimize efficiency and reduce waste.

10. Kanban

Kanban is a visual scheduling system used by Toyota to manage inventory and production. It provides real-time visibility of the production process, enabling efficient workflow management and inventory control. Kanban helps Toyota maintain optimal inventory levels, reduce lead times, and respond quickly to changes in customer demand.

11. Value Stream Mapping

Value Stream Mapping is a tool employed by Toyota to analyze and improve the flow of materials and information throughout the production process. It visually depicts the current state and desired future state of the value stream, highlighting areas of waste and opportunities for improvement. Value Stream Mapping enables Toyota to identify bottlenecks, reduce cycle times, and enhance overall efficiency.

12. Andon System

The Andon system is a visual management tool used by Toyota to alert operators and supervisors of abnormalities in the production process. It allows immediate identification and resolution of issues, minimizing downtime and preventing the production of defective products. The Andon system promotes quick problem-solving and encourages continuous improvement on the shop floor.

13. Just-in-Time (JIT)

Just-in-Time (JIT) is a production strategy pioneered by Toyota, aiming to deliver products and materials precisely when needed, in the right quantities.

By implementing JIT, Toyota minimizes inventory holding costs, reduces lead times, and enhances responsiveness to customer demand. JIT plays a vital role in streamlining production, eliminating waste, and improving overall efficiency.

Wrap Up

Toyota’s problem-solving methods have been instrumental in its success and have revolutionized the automobile manufacturing industry. By employing techniques such as the 5 Whys, PDCA, A3 problem-solving, and Lean Manufacturing, Toyota has continuously improved its processes, eliminated waste, and ensured high levels of quality.

These problem-solving methods, rooted in the Toyota Production System, have become benchmarks for other companies striving for excellence.

Did You Know?

Toyota is primarily known for producing automobiles, but the company also has divisions that manufacture other products. While it is most famous for its cars, trucks, and SUVs, the company has also been involved in the production of:

- Industrial Equipment: Toyota Industries Corporation, a subsidiary of Toyota, manufactures a wide range of industrial equipment, including forklifts, material handling equipment, and other machinery used in logistics and manufacturing.

- Robotics and Automation: Toyota has been investing in robotics and automation technologies. They have developed robots and automated systems for various industries, including manufacturing and healthcare.

- Engines and Components: In addition to assembling complete vehicles, Toyota manufactures engines and various components that are used not only in their vehicles but also in vehicles produced by other manufacturers.

- Financial Services: Toyota Financial Services provides financing and leasing options to customers and dealerships for purchasing Toyota vehicles.

- Hybrid Technology: Toyota is a pioneer in hybrid technology with models like the Toyota Prius. They produce hybrid powertrains that are used not only in their own vehicles but have also been licensed to other manufacturers.

- Bicycles: While not as widely recognized, Toyota has produced bicycles under their brand name, reflecting a broader approach to sustainable transportation.

Advantages of buying Toyota Products

Buying Toyota products, particularly their automobiles, comes with several advantages that have contributed to the company’s reputation for reliability, quality, and value. Here are some of the key advantages of buying Toyota products:

Reliability and Durability

Toyota vehicles are known for their exceptional reliability and longevity. The brand’s commitment to quality manufacturing and engineering means that Toyota owners often experience fewer breakdowns and costly repairs over the lifespan of their vehicles, contributing to lower ownership costs.

Resale Value

Toyota vehicles tend to retain their value well over time. Their reputation for reliability and widespread demand in the used car market leads to higher resale values compared to many other brands, providing better returns for owners when they decide to sell or trade in their vehicles.

Safety Innovations

Toyota places a strong emphasis on safety and is a leader in integrating advanced safety technologies into their vehicles. Many models come equipped with features such as adaptive cruise control, lane departure warning, automatic emergency braking, and pedestrian detection, contributing to safer driving experiences.

Fuel Efficiency and Hybrid Technology

Toyota has been a pioneer in hybrid technology with models like the Prius. Their hybrid vehicles offer impressive fuel efficiency, helping drivers save money on fuel costs while reducing their environmental impact by consuming less gasoline.

Wide Vehicle Range

Toyota offers a diverse lineup of vehicles that cater to a wide range of needs and preferences. Whether you’re looking for a compact car, a family-friendly SUV, a capable truck, or a hybrid vehicle, Toyota has options to suit various lifestyles.

Proven Quality

Toyota’s reputation for quality craftsmanship and meticulous attention to detail is reflected in their vehicles. The interior materials, fit and finish, and overall build quality contribute to a comfortable and enjoyable driving experience, enhancing the value of the ownership.

These advantages collectively make Toyota products an attractive choice for consumers seeking reliable, safe, fuel-efficient, and high-quality vehicles that hold their value well over time.

Also Read: Does Progressive Cover Towing? (8+ Free Services)